Wind turbine ANTARIS 7.5 kW grid connected

More info

" Made in Germany 7.5 Kw wind turbine "

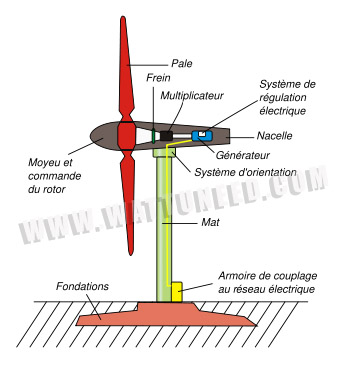

The ANTARIS wind turbine is a wind energy system that is ideally suited to inland sites. It is designed specifically for feeding power into the grid, charging batteries (24 V / 48 V etc.) and for supporting heating systems.

Thanks to its extremely robust and well thought-out design the ANTARIS wind turbine system is also suitable for stormy regions, with different optional repeller diameters (2.30 - 6.40 m).

The hand-laminated repeller blades benefit from a computer-designed aerodynamic profile. Needless to say, each blade is statically and dynamically balanced, carries an identification number and comes with relevant documentation.

The drive system of the ANTARIS small wind turbine system follows a simple logic: Fewer rotating components reduce the mechanical load and increase the technical operating life.

The maintenance and servicing is reduced (including less wearing parts, no gearbox oil change) and the operating costs drop. The rotor hub and permanent magnet generator are directly connected together as a fixed unit without gears. The rotor unit is mounted on a rotating axis with a high-strength material. In comparison with conventional gearing systems with numerous bearings in the moving drive train the ANTARIS operates with two relatively slow running rolling-contact bearings.

The same applies for the tilting unit, which is only activated by the wind and thus operates absolutely free of wear. For safety the ANTARIS has two high-quality stainless steel mufflers installed, which protect the corresponding end stops. The steels used are all provided with a test certificate, which documents the grade of the steel.

The welding joints are only carried out by certified welders. After the blanks have been manufactured all steel parts are galvanised under high temperature. This galvanising process has significant advantages for corrosion protection compared to conventional (hot-dip galvanisation) galvanisation processes. With the high-temperature galvanisation we offer you the most effective method for protecting all parts against corrosion that are responsible for safety and operation under taxing demands of the elemental weather conditions.

Technical Specifications

Generator

- Permanent-magnet rotor, brushless, gearless, maintenance-free

- Extremely strong permanent magnets for a high level of efficiency

- (NdFeBo permanent magnets, resistent to temperatures up to 150° C)

- 3-phase current

- Separate rectifier

- Either direction of rotation

- Voltage 0-1000 V

- Start of feed-in at approx. 75 rpm

- Power: 7.500 watts at 330 rpm and 400 V

- Evenly rising power curve

- Weight: 87kg

- Aluminium housing, surface cooling, base anchoring

- Gondola housing in GR

- Protection class IP56

Rotor

- Hub connection with aluminium flange and pressure-relief plate

- Stainless-steel screw connections with locknuts

- Three rotor blades in glass-fibre / carbon-fibre laminate

- Computer-designed aerodynamic profile

- Winglets on blade tips to minimise noise

- Approx. m in diamater

- Weight of each blade: approx. 9.2 kg

- Dynamically balanced

- Direction of rotation anticlockwise viewed from front

- Max. rotational speed 300 rpm

- GRP spinner cap

- Rotor colour to client specification

Support element comprising

- Wind vane (weatherproof HDPE, off-white, slightly transparent)

- Square stainless-steel tube as support element

- All screw connections in stainless steel and fitted with locknuts

- Steel bracket as support for generator, configured for plug-in connection with azimuth bearing, fully galvanised

- Protected by patented rotor-blade positioning system

- Mast adapter with flange connector (tube 139 mm)

Storm protection

- Rotor-blade positioning (“helicopter position”)

- Control electronics with turbine controller

Control cabinet

- Control system with voltage monitor

- 1-phased grid-feed in (Smart!wind Inverter 7.5 kW)

- Control electronics with 3-phased turbine controller

- Connections / plug connectors protected against polarity reversal

- Controlling of the alternator phases during turbinemode

- Emergency-OFF switch

- Reset switch with key (removable)

- Rectifier, display etc.

- 3.0 kW braking resistance

Smart Power Electronics 7.5 kW inverter

Smart Power Electronics 7.5 kW inverter

MODERN - FLEXIBLE - POWERFUL

Max. 20 kW wind turbine load (SW-10)

Pairing the three-phase network with 10 kW (SW-10)

Flexible and intelligent management of clean power, heating, battery and discharge charges through 4 separate CC energy outlets

Energy counter for power and heating

Control of reactive power

Battery buffer interface - optional

PROFITABLE - SURE

Built-in control functions for a wind turbine Intelligent and finely resolute control of the characteristic curve for optimal wind use

Characteristic curve freely selectable depending on voltage or speed

Many monitoring functions, such as wind speed or speed

Switch to shut down KWEA with other safety features

Compact

Direct connection of the particle generator without additional equipment

Wide range of input voltage for particle generators

Compact design of the case with a separate aperture connection area

Passive convection cooling on a wide range of performance

Integrated network/system protection (NA protection according to VDE AR-N 4105)

Communicative

Built-in graphic display

Built-in web server

Practical PC Smart!wind Explorer use and set-up interface

APPLICATION AREAS

Small wind turbines

Small hydroelectric power plants

Mini-cogeneration

Characteristic

| General data | SW-7.5 |

| Size | 656 x 472 x 234 mm |

| Weight | 42 kg |

| Protective class | IP54 |

| Cooling | Passive air/fan controlled according to demand |

| How it works in the temperature range | -25 degrees Celsius ... -40 degrees Fahrenheit - automatic decommissioning |

| Global efficiency | No more than 94%. |

| Clean consumption | 18 W - Waiting |

| 83 W - Active offer | |

| Entry generator side | |

| Generator type | excited constantly / 3 phases |

| Generator-side lifter | B6 |

| 60...500 VLL | |

| 310 ... 500 VLL - for a full power of 10 kW | |

| 600 VLL - maximum | |

| Entry voltage range (driver-driver) | 20 A - face value |

| Entry current (nominal value) | 40 A - max. 5 s |

| Entry power | 15 kW - face value |

| Entry current (nominal value) | 30 kW - max. 5 s |

| Maximum value limited by load resistance | 0 Hz ... 150 Hz |

| Frequency of entry | Isolation control |

| Monitoring generators | Temperature control |

| Speed control | |

| Exit sector side | |

| Inverter sector side | IGBT B6 |

| Number of phases | 3 |

| Output power (nominal value) | 7.5 kW |

| Exit tension | 400 VLL - face value |

| 318 ... 460 VLL - eligible reach | |

| Outfed current (nominal value) | 0 ... 11 A |

| Exit frequency | 0 Hz ... 150 Hz |

| Separation concept | without transformer - no galvanic insulation |

| Power factor - cos | 3% |

| Power factor - cos | regulated to 1 - regulation according to VDE AR-N 4105 |

| Resistance to short circuits | Current control |

| Network/system protection - ENS | VDE AR-N 4105 |

|  |